insulaion material-6630-class B DMD insulation paper

- Delivery Time:

- 4 Days

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China (Mainland) |

|---|

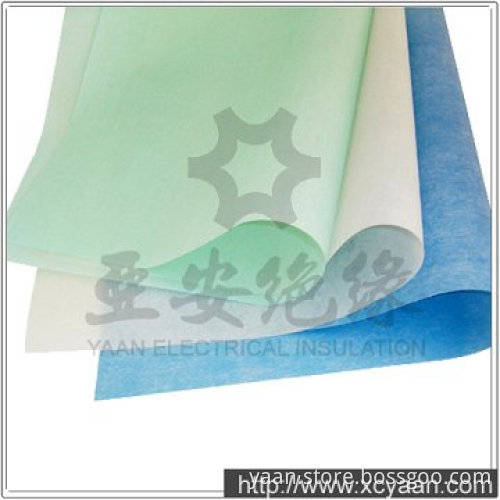

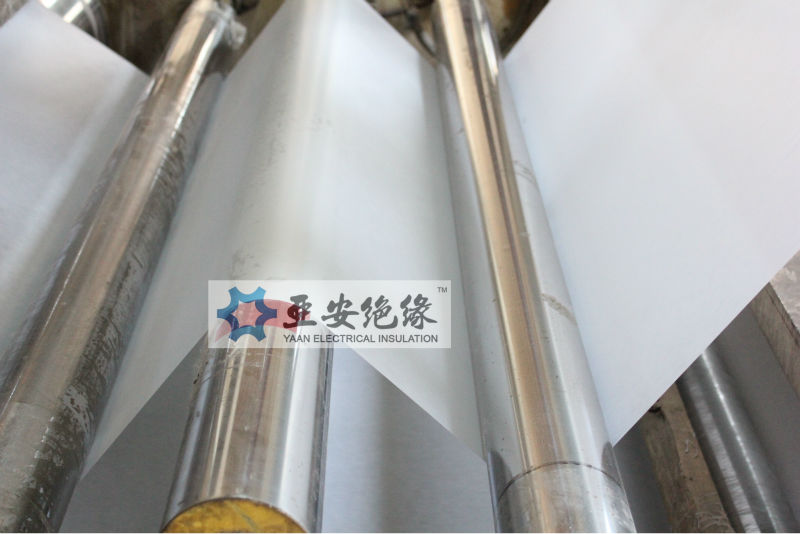

class B DMD insulation paper is a triple-layer electrical insulation material of thermal class 130 degree, consisting of PET film covered on both sides with polyester felt. This DMD has excellent electrical, mechanical, and impregnating properties. Application of class B DMD insulation paper: Class B DMD inslation paper is mainly used as a solt liner, slot closure, phase and turn-to-turn insulation in electrical motors, it can be also used as interlayer insulation in transformers and other electrical machines and appliances.

class B DMD insulation paper is a triple-layer electrical insulation material of thermal class 130 degree, consisting of PET film covered on both sides with polyester felt. This DMD has excellent electrical, mechanical, and impregnating properties. Application of class B DMD insulation paper: Class B DMD inslation paper is mainly used as a solt liner, slot closure, phase and turn-to-turn insulation in electrical motors, it can be also used as interlayer insulation in transformers and other electrical machines and appliances.

Related Keywords Related Keywords

You May Also Like

You May Also Like

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

![[INSULATING PAPERS] ul approved insulating papers](https://bsg-i.nbxc.com/product/76/d2/ab/bc67669415935e604277d555bb.jpg@4e_360w_360h.src|watermark=2&color=I0ZGRkZGRg%3D%3D&type=ZHJvaWRzYW5zZmFsbGJhY2s%3D&size=16&p=9&t=80&s=20&text=eWFhbi5zdG9yZS5ib3NzZ29vLmNvbQ%3D%3D)

![[BETTER THERMAL INSULATION MATERIAL]6641 F-DMD Cheap thermal insulation material](https://bsg-i.nbxc.com/product/4f/e3/e2/90311bef3eaa917fedee5131a1.jpg@4e_360w_360h.src|watermark=2&color=I0ZGRkZGRg%3D%3D&type=ZHJvaWRzYW5zZmFsbGJhY2s%3D&size=16&p=9&t=80&s=20&text=eWFhbi5zdG9yZS5ib3NzZ29vLmNvbQ%3D%3D)